HOME • ANIMAL FEED PELLET LINE

Different Animal Feed Mill Solutions

Livestock and poultry and ruminant feed ingredients include corn, wheat, barley, oats, sorghum, soybeans, soybean meal, fish meal, amino acids, mixed meal, whey powder, oil, meat and bone meal, cereals, feed additives, etc. In addition, ruminant feed also contains crude fiber raw materials such as grass, hay and straw. At the same time, different animal feeds also need to add liquid raw materials, such as oil, molasses, liquid amino acids, lactic acid, etc.

The following introduces different livestock and poultry feed production processes:

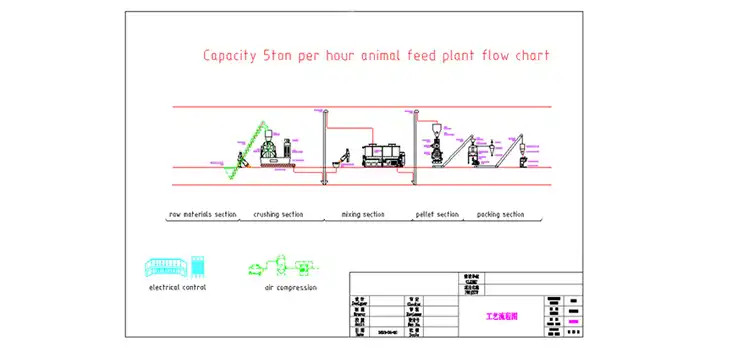

2-5 Tons Pellet Feed Line

This process can produce various livestock and poultry animal pellet feeds. The ring die aperture is 2-8mm and the output is 2-5T/H. The production process is feeding various raw materials according to the formula – crushing – mixing – granulating – cooling – packaging

Technical Parameters

| Name | Total power | Capacity | Air compressor | Steam volume |

|---|---|---|---|---|

| Parameter | 148KW | 2-5T/H | 7.5KW1.05cubic/min | 0.3T/H |

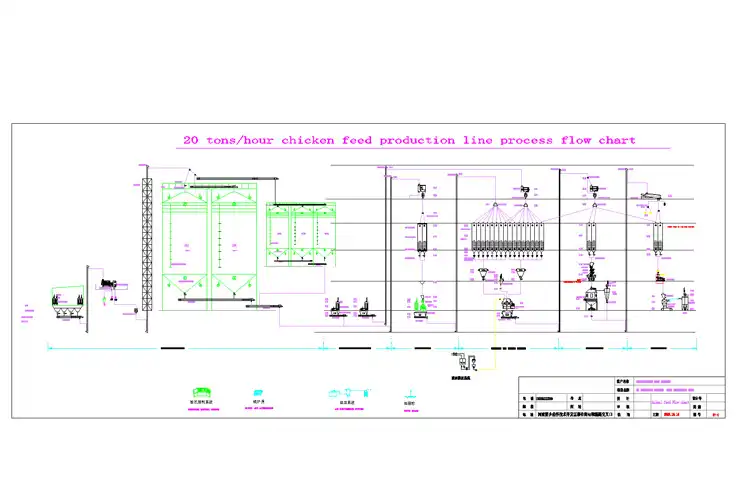

10T/H, 15T/H, 20T/H Livestock and Poultry Feed Pellet Line

This process can produce various livestock and poultry animal pellet feeds. The ring die aperture is 2-8mm and the output is 10-30T/H. The production process is silo section-feeding-crushing-batching-mixing-granulation-cooling-crushing-packaging. The mixer is equipped with a liquid adding system. If the ruminant feed is produced, a conditioner can be used to add molasses. If the pellet feed for broilers, ducks, and fish is produced, a grease spraying equipment after the pellet feed can be used. After the finished product is packaged, the optional automatic palletizer equipment can save manpower.

Technical Parameters

| Name | Total power | Capacity | Air compressor | Steam volume | Boiler |

|---|---|---|---|---|---|

| 10T/H parameters | 386KW | 10T/H | 15KW 2.4 cubic meters/minute | 0.7T/H | 1 ton |

| 15T/H parameters | 538KW | 15T/H | 22KW 3.6 cubic meters/minute | 1.05T/H | 1.5 ton |

| 20T/H parameters | 680KW | 20T/H | 22KW 3.6 cubic meters/minute | 1.4T/H | 2 ton |

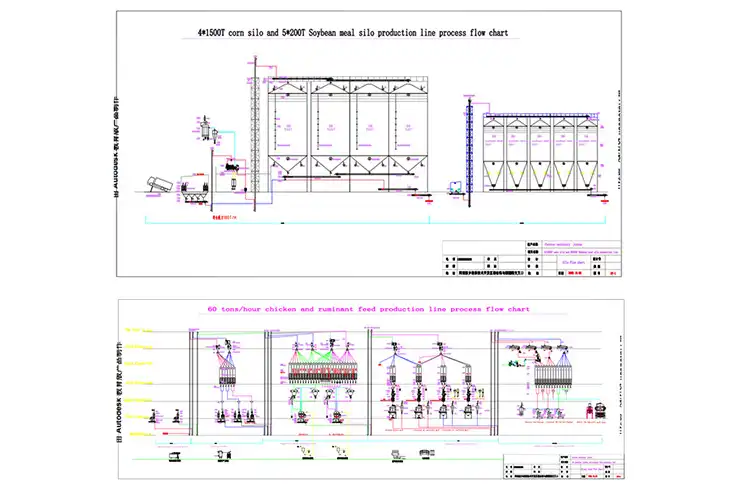

60T/H Livestock and Poultry Feed Pellet Line (4*15T/H Pellet Lines)

This process can produce various livestock and poultry animal pellet feeds. The ring die aperture is 2-8mm and the output is 60T/H. The production process is silo section-feeding-crushing-batching-mixing-granulation-cooling-crushing-packaging. The dual-ingredient and dual-mixing system can produce animal feeds of different formulas at the same time. The mixer is equipped with two sets of liquid adding systems. If the ruminant feed is produced, a conditioner and molasses adding equipment can be optional. If the broiler, duck, and fish pellet feed is produced, the mixer can be equipped with a conditioner. Optional equipment for spraying grease after pellet feed. After the finished product is packaged, the optional automatic palletizer equipment can save manpower.

Technical Parameters

| Name | Total power | Capacity | Compressed air | Air compressor | Steam volume | Boiler |

|---|---|---|---|---|---|---|

| 60T/H parameters | 2020KW | 60T/H | 7.5 cubic meters/minute | 45KW | 3.6-4.2T/H | 6 ton |

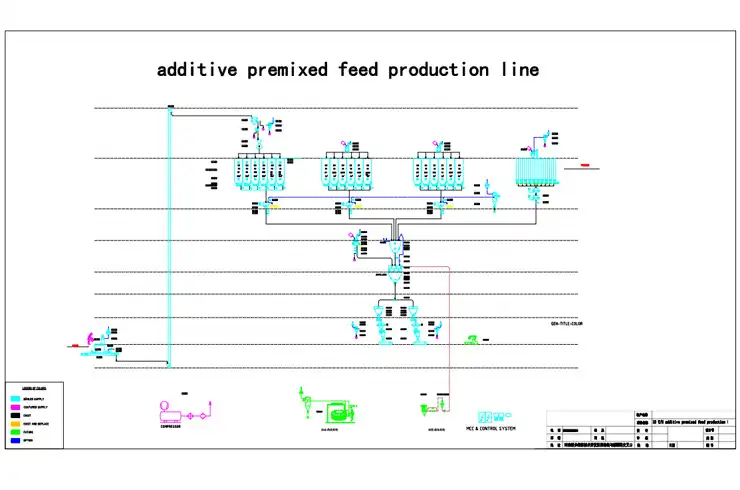

2000KG/P Fully Automatic Batching and Premix Line

This process can produce various livestock, poultry, and aquatic animal premixes with an output of 10T/H. The production process is feeding–batching–mixing–packaging. Some silos, mixers, and finished product sections are all made of 304 stainless steel. The batching accuracy can be within two thousandths, and each equipment has low residual content. Special processing has been done in dust removal to ensure that the dust content in the production environment is very low. After the finished product is packaged, an automatic palletizer can be optionally equipped to save manpower.

Technical Parameters

| Name | Total power | Capacity | Compressed air | Air compressor |

|---|---|---|---|---|

| 10T/H parameters | 182KW | 10T/H | 3.6 cubic meters/minute | 22KW |

Related Cases

What Can We Do For You?

Tel:

0373-3876888

Email:

Email:

Address:

Xinxiang City, Henan Province, China