HOME • AQUATIC FEED LINE

Different Expanded Aquatic Feed Solutions

Puffed aquatic feed raw materials include soybean meal, rapeseed meal, flour, corn, starch, blood meal, fish meal, pork meal, amino acids, oils, meat and bone meal, chicken meal, feed additives, etc. At the same time, different extruded feeds also need to add liquid raw materials, such as vegetable oil, fish oil, liquid amino acids, fish slurry, etc.

The following introduces different extruded feed production processes:

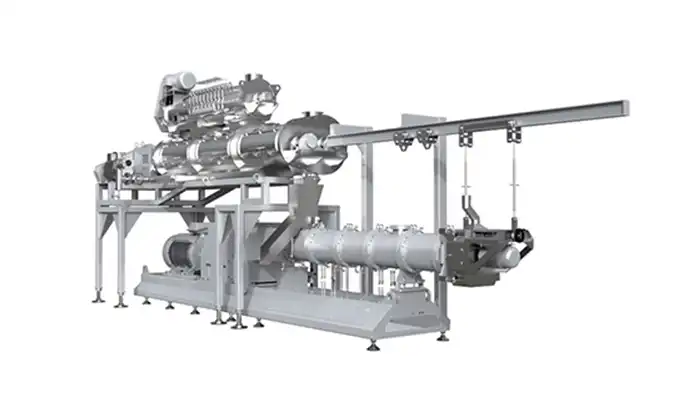

Extruded Feed Production Line

This process can produce various puffed aquatic feeds. The ring die aperture is 0.8-8mm and the output is 1-15T/H. The production process is various raw material feeding-ingredient mixing-primary crushing-ultrafine crushing-secondary batching mixing- Puffing-drying-screening-vacuum spraying-cooling-screening-packaging.

1T/H 2-3T/H 5-7T/H 10T/H 15T/H Extrusion Line

Technical Parameters

| Name | Total power | Capacity | Compressed air | Air compressor | Amount of steam (steam drying) | Boiler (steam drying) | Steam volume (gas drying) | Boiler (gas drying) |

|---|---|---|---|---|---|---|---|---|

| 1T/H parameter | 386KW | 1T/H | 2.4 cubic meters/minute | 15KW | 0.7T/H | 1 ton | 0.7T/H | 1 ton |

| 2-3T/H parameter | 538KW | 2-3T/H | 2.4 cubic meters/minute | 15KW | 1.05T/H | 1.5 ton | 0.3T/H | 0.5 ton |

| 5-7T/H parameter | 680KW | 5-7T/H | 3.6 cubic meters/minute | 22KW | 2.4T/H | 3 ton | 0.7T/H | 1 ton |

| 10T/H parameter | 1350KW | 10T/H | 3.6 cubic meters/minute | 22KW | 3.5T/H | 4 ton | 1.4T/H | 2 ton |

| 15T/H parameter | 1800KW | 15T/H | 7.5 cubic meters/minute | 45KW | 5T/H | 6 ton | 1.2T/H | 2 ton |

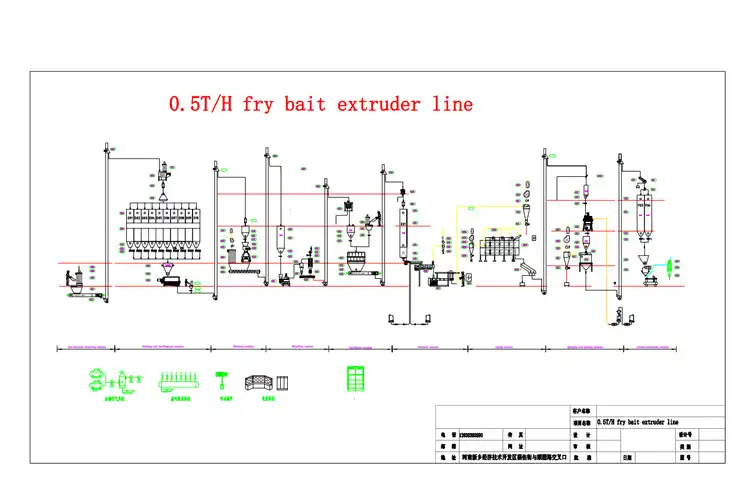

0.3-0.8mm Micro-Particle Puffed Bait Line

This process can produce various fish baits, with a mold aperture of 0.3-0.8mm and an output of 200-500T/H. The production process is feeding – batching mixing – primary crushing – ultrafine crushing – secondary batching – mixing – high imitation screening – puffing -Drying-screening-spraying-cooling-screening-packaging. The fineness of the ultrafine powder needs to reach 99% and over 100 mesh, and the dryer and cooler are special equipment.

Technical Parameters

| Name | Total power | Capacity | Compressed air | Air compressor | Steam volume | Boiler |

|---|---|---|---|---|---|---|

| Parameter | 185KW | 200-500kg/H | 2.4 cubic meters/minute | 15KW | 0.2-0.3T/H | 0.5 ton |

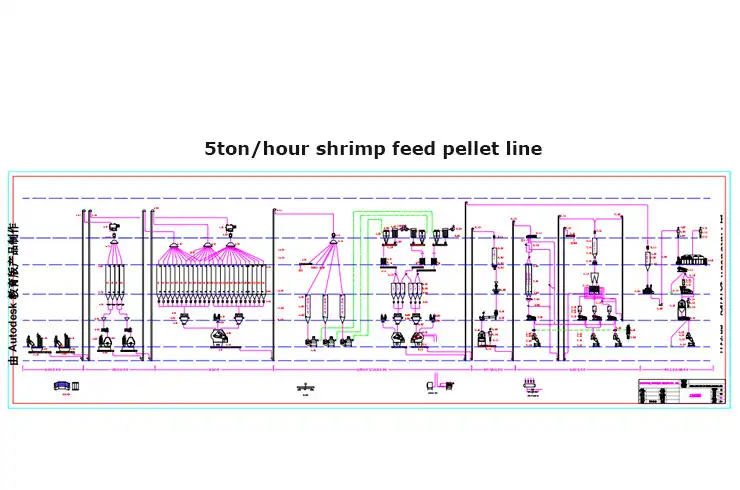

Shrimp Feed Production Line

This process can produce various shrimp feeds. The ring die aperture is 1.0-2.0mm, and the single-line output is 1-5T/H. The production process is various raw material feeding-ingredient mixing-primary crushing-ultrafine crushing-secondary batching mixing. -Granulation-ripening-cooling-crushing-screening-packaging.

Features:

- The crushing fineness requirement is very fine, 95% passes 80 mesh.

- High ripening requirements: the conditioner must be equipped with four layers, namely differential conditioner + quality preserver + quality preserver + single-axis conditioner.

- It needs to be post-cured and simmered in a post-curing device for more than 60 minutes after granulation to improve water resistance.

- The crushed materials need to use a fine-toothed crusher, and a powder cleaner is required before packaging the finished product to ensure that the powder content of the finished product is less than three thousandths.

Related Cases

What Can We Do For You?

Tel:

0373-3876888

Email:

Email:

Address:

Xinxiang City, Henan Province, China