HOME • PET FOOD PRODUCTION LINE

Puffed Pet Food Staple Food Solution

Puffed pet food raw materials include soybean meal, corn, flour, rice, bran, fish meal, chicken meal, amino acids, oils, meat and bone meal, fresh meat pulp, pet food additives, etc. At the same time, different puffed staple foods also need to add liquid raw materials, powdery flavoring agents, and feed attractants, such as vegetable oil, fish oil, meat pulp, enzymatic chicken liver powder, etc.

The following introduces different puffed pet food production processes:

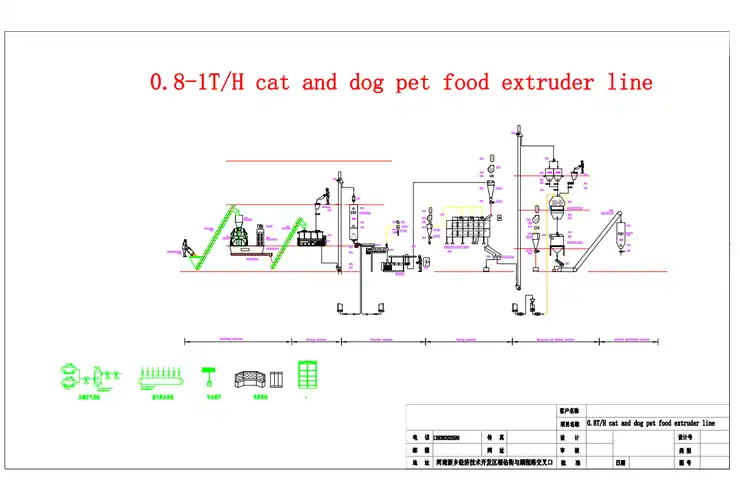

Simple Puffed Staple Food Production Line

This process can produce various puffed pet foods. The ring die aperture is 2-6mm and the output is 0.8-1T/H. The production process is feeding various raw materials – crushing – mixing – puffing – drying – screening – spraying – Cool-sieve-pack.

Technical Parameters

| Name | Total power | Capacity | Compressed air | Air compressor | Steam volume | Boiler |

|---|---|---|---|---|---|---|

| 1T/H parameters | 185KW | 1T/H | 1.05 cubic meters/minute | 7.5KW | 0.4T/H | 0.5 ton |

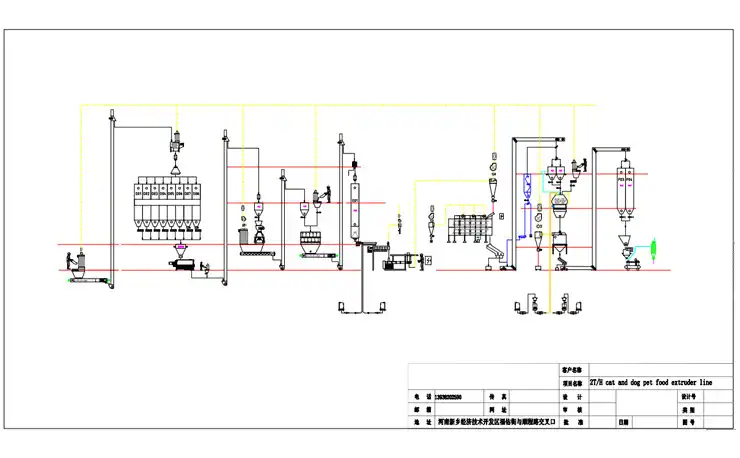

2-3T/H Puffed Pet Food Technology

Technical Parameters

| Name | Total power | Capacity | Compressed air | Air compressor | Amount of steam (steam drying) | Boiler (steam drying) | Steam volume (gas drying) | Boiler (gas drying) |

|---|---|---|---|---|---|---|---|---|

| 2-3T/H parameters | 450KW | 2-3T/H | 2.4 cubic meters/minute | 15KW | 0.9T/H | 1.0 ton | 0.3T/H | 0.5 ton |

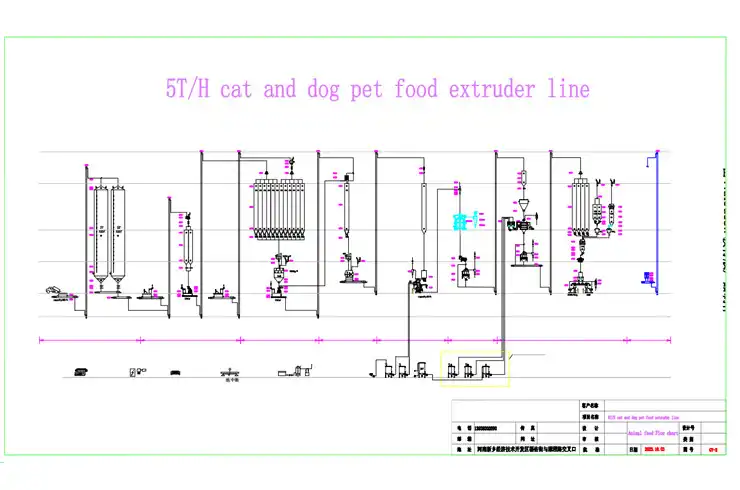

5T/H, 10T/H Puffed Pet Food Technology

Technical Parameters

| Name | Total power | Capacity | Compressed air | Air compressor | Amount of steam (steam drying) | Boiler (steam drying) | Steam volume (gas drying) | Boiler (gas drying) |

|---|---|---|---|---|---|---|---|---|

| 5T/H parameters | 450KW | 2-3T/H | 2.4 cubic meters/minute | 15KW | 1.75T/H | 2 tons | 0.5T/H | 1 ton |

| 10T/H parameters | 450KW | 2-3T/H | 2.4 cubic meters/minute | 15KW | 3.5T/H | 4 tons | 0.8-1T/H | 1.5 ton |

Low Temperature Baked Grain Production Line

This process can produce various low-temperature baking staple foods for cats and dogs. The shape can be customized. The output is 200-500kg/H. The production process is ingredient mixing-pressing mold demoulding-baking and shaping-drying-screening-spraying-cooling. -Screening-Packaging.

Related Cases

What Can We Do For You?

Tel:

0373-3876888

Email:

Email:

Address:

Xinxiang City, Henan Province, China